BLOG

At Colorado Concrete Repair, we understand that safety is a paramount concern in food production facilities. The right flooring can play a crucial role in creating a safe working environment, helping to reduce accidents and maintain compliance with health regulations. Concrete flooring has emerged as an excellent choice for enhancing safety in these settings. In this blog, we’ll explore how food production facilities concrete flooring enhances a safe environment. 1. Slip-Resistant Surfaces One of the most significant safety features of concrete flooring is its ability to be treated with slip-resistant additives. In food production facilities, spills and wet conditions are common, which can create hazardous walking surfaces. By incorporating slip-resistant textures into concrete flooring, facilities can significantly reduce the risk of slip-and-fall accidents, ensuring a safer working environment for employees. 2. Durable and Impact-Resistant Food production facilities concrete flooring is known for its durability and strength, making it resistant to wear and tear from heavy machinery and foot traffic. In busy food production environments, where equipment like forklifts and pallet jacks are frequently used, durable flooring is essential. Concrete can […]

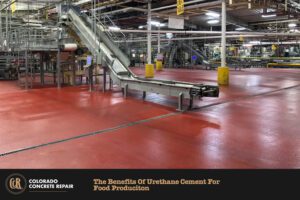

...READ MOREAt Colorado Concrete Repair, we understand the unique challenges faced by food production facilities when it comes to flooring solutions. The right flooring can significantly impact safety, hygiene, and operational efficiency. Urethane cement flooring has emerged as a leading choice for the food industry, offering numerous benefits that make it an ideal solution. In this blog, we’ll explore the key benefits of urethane cement for food production. 1. Exceptional Durability Urethane cement is renowned for its durability, making it perfect for food production environments that experience heavy foot and vehicle traffic. This flooring material can withstand the weight of heavy machinery, carts, and pallets without showing signs of wear. Its resistance to impacts and abrasions ensures that it maintains its integrity over time, reducing the need for costly repairs or replacements. 2. Thermal Shock Resistance In food production, facilities often deal with extreme temperature variations—from freezing cold storage areas to hot cooking environments. Urethane cement is designed to handle these fluctuations without cracking or degrading. This thermal shock resistance is essential in maintaining the flooring’s structural integrity and longevity, ensuring […]

...READ MOREAt Colorado Concrete Repair, we specialize in providing top-tier flooring solutions for industrial environments. One of the most effective and durable options we recommend to our clients is urethane cement industrial flooring. Designed to withstand the harshest conditions, urethane cement is ideal for industries that require high-performance flooring solutions. In this blog, we’ll discuss why urethane cement industrial flooring is the ultimate choice. 1. Exceptional Durability Urethan is known for its incredible durability. This type of flooring is designed to endure heavy machinery, high foot traffic, and constant wear and tear without breaking down. It is impact-resistant and can handle the demands of industries such as manufacturing, food processing, and chemical production. Whether your facility experiences frequent forklift traffic or heavy loads, urethane cement will maintain its integrity over time. 2. Thermal Shock Resistance One of the standout features of urethane cement is its ability to resist thermal shock. Industrial environments often experience significant temperature fluctuations, especially in areas where extreme heat or cold is present, such as commercial kitchens, breweries, and cold storage facilities. Unlike other flooring materials that […]

...READ MOREAt Colorado Concrete Repair, we understand that maintaining a hygienic environment is crucial in the food production industry. Choosing the right flooring is an essential part of achieving and sustaining cleanliness and safety standards. Concrete flooring in food production, especially when treated with specialized coatings, offers numerous hygienic benefits that make it an ideal choice for facilities. In this blog, we’ll explore the key advantages of concrete flooring in food production facilities from a hygiene perspective. 1. Seamless Surface One of the most significant benefits of concrete flooring is its seamless nature. Unlike traditional flooring options, such as tiles or vinyl, which can have grout lines and seams, concrete creates a continuous surface that eliminates cracks and crevices where dirt, bacteria, and contaminants can accumulate. This seamless design simplifies cleaning and reduces the risk of cross-contamination in food production areas. 2. Non-Porous and Moisture-Resistant Concrete flooring, when properly sealed with high-quality epoxy or urethane coatings, becomes a non-porous surface. This characteristic prevents moisture and liquid from seeping into the flooring, minimizing the growth of mold and bacteria. In food production, […]

...READ MOREAt Colorado Concrete Repair, we understand that food production facilities demand flooring systems that meet strict industry standards while also withstanding the harsh conditions of daily operations. One of the most effective solutions available for industrial food production flooring is Methyl Methacrylate (MMA) resin. This versatile flooring option offers a range of benefits, making it an ideal choice for food processing environments. 1. Rapid Installation and Cure Time In the fast-paced world of food production, every minute counts. Methyl Methacrylate (MMA) resin is known for its exceptionally fast curing time, typically hardening within just two hours after installation. This quick installation process minimizes downtime, allowing businesses to resume operations faster than they would with traditional concrete or epoxy systems. For facilities that operate 24/7, such as food processing plants, Methyl Methacrylate (MMA) resin’s rapid curing offers a critical advantage. 2. High Resistance to Temperature Extremes Food production facilities often experience extreme temperature fluctuations, from the heat of industrial ovens to the cold storage of freezers. Methyl Methacrylate (MMA) resin flooring is designed to withstand both high and low temperatures without […]

...READ MOREAt Colorado Concrete Repair, we pride ourselves on providing flooring solutions that meet the specific demands of industrial food production. One of the most popular options for food production facilities is Methyl Methacrylate resin. Methyl Methacrylate resin offers many advantages, but like any material, it also comes with a few drawbacks. In this blog, we’ll explore the pros and cons of Methyl Methacrylate resin for industrial food production flooring. The Pros 1. Rapid Installation and Cure Time MMA resin’s biggest advantage is its extremely fast curing time. In comparison to epoxy or polyurethane systems, which can take days to fully cure, MMA resin hardens in as little as two hours. This speed minimizes operational downtime, making it perfect for busy food production facilities that need to maintain constant operations. 2. Durability and Resistance to Extreme MMA resin is highly durable and capable of withstanding significant temperature fluctuations. Food processing environments often experience extremes—such as the heat of ovens and the cold of freezers. MMA resin performs exceptionally well in both high and low temperatures without cracking or deteriorating, ensuring long-lasting […]

...READ MORE