BLOG

When it comes to pharmaceutical manufacturing and research facilities, flooring is more than just a surface to walk on. It plays a crucial role in maintaining safety, cleanliness, and compliance with industry regulations. One of the most critical types of flooring in these environments is pharma ESD flooring. This specialized flooring helps prevent electrostatic discharge (ESD), which can cause significant damage to sensitive electronic equipment and compromise the integrity of pharmaceutical products What Is Pharma ESD Flooring? Pharma ESD flooring is designed to minimize the buildup of static electricity and safely dissipate any electrostatic charges that could potentially harm personnel or equipment. In a pharmaceutical setting, where precision and product purity are paramount, the need for ESD-safe flooring cannot be overstated. These flooring systems often incorporate conductive or dissipative materials that work in conjunction with grounding methods to ensure static charges are controlled effectively. Why Is Pharmaceutical ESD Flooring Essential? Protection of Sensitive Equipment Pharmaceutical laboratories and manufacturing plants use high-tech electronic instruments that are highly susceptible to electrostatic discharge. Even a small spark can damage these sensitive components, leading […]

...READ MOREWarehouse floor striping is a crucial aspect of maintaining a safe, organized, and efficient workspace. Whether you’re managing a distribution center, a manufacturing plant, or a storage facility, clearly marked floors help streamline operations and reduce the risk of workplace accidents. At Colorado Concrete Repair, we specialize in high-quality warehouse floor striping that meets OSHA standards and ensures durability in high-traffic environments. Why Warehouse Floor Striping Matters Warehouse floor striping serves multiple purposes, from improving workflow to enhancing safety. Here are a few key reasons why investing in professional striping services from Colorado Concrete Repair is a smart decision: Improved Safety – Clearly marked walkways, forklift lanes, and hazard zones help prevent accidents by guiding employees and equipment operators safely through the facility. Optimized Workflow – Floor striping creates designated pathways and storage areas, reducing congestion and improving efficiency. Regulatory Compliance – Many industries are required to follow OSHA and other safety guidelines that mandate proper floor markings. Aesthetic and Professional Appeal – A well-marked warehouse looks organized and professional, leaving a good impression on employees, clients, and inspectors. The […]

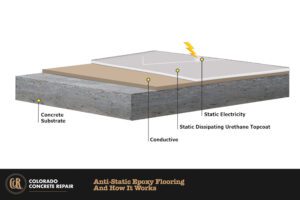

...READ MOREWhat is Anti-Static Epoxy Flooring? Anti-static epoxy flooring is a specialized flooring solution designed to prevent the buildup of static electricity. This type of flooring is particularly essential in environments where static discharge can damage sensitive electronic equipment, ignite flammable materials, or interfere with critical operations. At Colorado Concrete Repair, we install high-quality anti-static epoxy flooring to enhance safety and efficiency in various industries. This flooring system incorporates conductive or dissipative materials that help control electrostatic discharge (ESD). The primary purpose of anti-static epoxy flooring is to create a grounded surface that safely directs static electricity away from equipment and personnel, reducing the risk of accidental damage or hazards. How Does Anti-Static Flooring Work? Anti-static flooring works by incorporating conductive materials that dissipate electrostatic charges. When people walk across a floor, friction between their shoes and the surface can generate static electricity. If not controlled, this static charge can transfer to sensitive equipment or materials, leading to malfunctions, fires, or explosions in certain environments. The key components that make anti-static flooring effective include: Conductive Additives – The epoxy coating is […]

...READ MOREWhen it comes to ensuring a strong and durable bond between coatings and concrete surfaces, shot blasting is one of the most effective surface preparation methods. At Colorado Concrete Repair, we understand the importance of proper floor preparation to maximize adhesion and longevity. In this blog, we’ll explore the science behind shot blasting industrial floors and why it’s a crucial step for any flooring installation or repair project. What is Shot Blasting Concrete? Shot blasting is a mechanical surface preparation technique that involves propelling small steel abrasive particles (known as shot) at high velocity onto a concrete surface. This process removes surface contaminants, opens the pores of the concrete, and creates the perfect texture for coatings, epoxy, or overlays to bond effectively. Shot blasting industrial floors is essential in industries where durable and long-lasting flooring solutions are required. Unlike traditional grinding methods, shot blasting is a dust-free process when used with proper vacuum systems. It not only cleans but also profiles the surface, making it ideal for areas that require high-performance coatings. The Science Behind Better Adhesion Adhesion is a […]

...READ MOREIn industries where sensitive electronics, combustible materials, and high-precision equipment are present, flooring plays a crucial role in maintaining safety and efficiency. One of the best solutions for such environments is ESD epoxy flooring. This type of flooring is specifically designed to dissipate electrostatic discharge (ESD), which can be harmful to electronics, create safety hazards, and even cause costly operational downtime. At Colorado Concrete Repair, we specialize in providing high-quality ESD epoxy flooring solutions for warehouses, laboratories, and other industrial facilities. If you are looking to enhance workplace safety, durability, and compliance, here are the top benefits of investing in ESD epoxy flooring. 1. Prevents Electrostatic Discharge (ESD) Damage One of the main reasons warehouses and labs invest in ESD epoxy flooring is to prevent electrostatic discharge from damaging sensitive equipment and materials. ESD can be a significant issue in environments that deal with microelectronics, pharmaceuticals, and volatile chemicals. Standard flooring materials can generate and retain static electricity, which can lead to unexpected discharges. ESD epoxy flooring is specially formulated to safely dissipate static charges, reducing the risk of damage […]

...READ MOREWhen it comes to preparing concrete surfaces for coatings, overlays, or repairs, shot blasting concrete is one of the most effective and efficient methods available. This technique not only enhances adhesion but also removes contaminants, creating a clean and roughened surface that ensures long-lasting results. At Colorado Concrete Repair, we specialize in using shot blasting to prepare concrete surfaces, guaranteeing optimal conditions for any subsequent treatment. What is Shot Blasting? Shot blasting concrete is a surface preparation technique that involves propelling small steel beads (or “shot”) at high velocity onto a concrete surface. This process strips away debris, coatings, and weak concrete layers while simultaneously roughening the surface. Unlike other preparation methods like grinding or chemical treatments, shot blasting is dust-free when used with proper vacuum systems and is environmentally friendly, as it does not involve harmful chemicals. Why Shot Blasting is Essential 1. Enhances Adhesion for Coatings and Overlays One of the primary reasons for shot blasting concrete is to improve the adhesion of coatings, sealers, and overlays. Without proper surface preparation, coatings may fail prematurely, leading to costly […]

...READ MORE