Be In The Know.

Blog

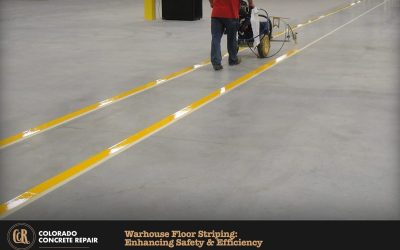

Warehouse Floor Striping: Enhancing Safety & Efficiency

Warehouse floor striping is a crucial aspect of maintaining a safe, organized, and efficient workspace. Whether you're managing a distribution center, a manufacturing plant, or a storage facility, clearly marked floors help streamline operations and reduce the risk of...

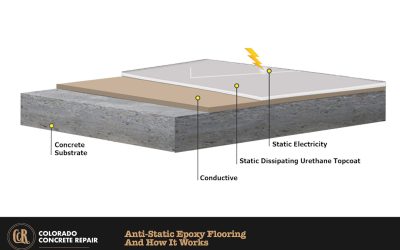

Anti-Static Epoxy Flooring and How It Works

What is Anti-Static Epoxy Flooring?Anti-static epoxy flooring is a specialized flooring solution designed to prevent the buildup of static electricity. This type of flooring is particularly essential in environments where static discharge can damage sensitive...

The Science Behind Shot Blasting Industrial Floors for Better Adhesion

When it comes to ensuring a strong and durable bond between coatings and concrete surfaces, shot blasting is one of the most effective surface preparation methods. At Colorado Concrete Repair, we understand the importance of proper floor preparation to maximize...

Top Benefits of ESD Epoxy Flooring for Warehouses and Labs

In industries where sensitive electronics, combustible materials, and high-precision equipment are present, flooring plays a crucial role in maintaining safety and efficiency. One of the best solutions for such environments is ESD epoxy flooring. This type of flooring...

Why Shot Blasting Concrete is Essential for Surface Preparation

When it comes to preparing concrete surfaces for coatings, overlays, or repairs, shot blasting concrete is one of the most effective and efficient methods available. This technique not only enhances adhesion but also removes contaminants, creating a clean and...

The Ultimate Solution: Urethane Cement Commercial Kitchen Flooring

When it comes to commercial kitchen flooring, durability, hygiene, and performance are non-negotiable. Colorado Concrete Flooring has been at the forefront of providing top-tier flooring solutions that meet the demanding needs of commercial kitchens across the state....

Polished Concrete Floors: Durability, Aesthetic Appeal, and More

When it comes to flooring options, polished concrete is rapidly gaining popularity in both residential and commercial spaces. Known for its sleek and modern appearance, polished concrete floors offer far more than just visual appeal. From unmatched durability to easy...

Methacrylate Concrete Industrial Floors: Ideal for Heavy Traffic Areas

When it comes to flooring solutions for high-traffic industrial spaces, durability and reliability are non-negotiable. Whether it’s a manufacturing facility, warehouse, or commercial hub, the floors must withstand constant use, heavy loads, and often harsh...

The Methacrylate Concrete Flooring Benefits For Construction Projects

When it comes to selecting the perfect flooring solution for construction projects, durability, versatility, and longevity are paramount. Colorado Concrete Flooring proudly offers an innovative and effective solution: methacrylate concrete flooring. This advanced...

Why Methyl Methacrylate Flooring is the Future of Flooring Solutions

If you’ve been looking for a reliable, high-performance solution for your concrete flooring needs, Methyl Methacrylate (MMA) is a material you need to know about. At Colorado Concrete Repair, we’ve embraced MMA as a cutting-edge solution that’s revolutionizing the...