Be In The Know.

Blog

The Benefits of Urethane Cement for Pharmaceutical Production

At Colorado Concrete Repair, we understand that safety is a paramount concern in food production facilities. The right flooring can play a crucial role in creating a safe working environment, helping to reduce accidents and maintain compliance with health regulations....

The Benefits of Urethane Cement for Food Production

At Colorado Concrete Repair, we understand the unique challenges faced by food production facilities when it comes to flooring solutions. The right flooring can significantly impact safety, hygiene, and operational efficiency. Urethane cement flooring has emerged as a...

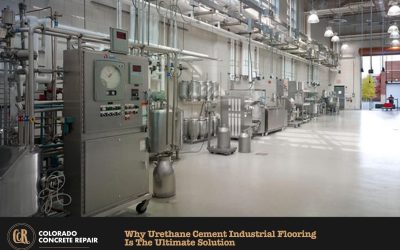

Why Urethane Cement Industrial Flooring is the Ultimate Solution

At Colorado Concrete Repair, we specialize in providing top-tier flooring solutions for industrial environments. One of the most effective and durable options we recommend to our clients is urethane cement industrial flooring. Designed to withstand the harshest...

The Hygienic Benefits of Concrete Flooring in Food Production

At Colorado Concrete Repair, we understand that maintaining a hygienic environment is crucial in the food production industry. Choosing the right flooring is an essential part of achieving and sustaining cleanliness and safety standards. Concrete flooring in food...

The Benefits of Methyl Methacrylate (MMA) Resin for Industrial Food Production Flooring

At Colorado Concrete Repair, we understand that food production facilities demand flooring systems that meet strict industry standards while also withstanding the harsh conditions of daily operations. One of the most effective solutions available for industrial food...

The Benefits and Drawbacks of Methyl Methacrylate (MMA) Resin for Industrial Food Production Flooring

At Colorado Concrete Repair, we pride ourselves on providing flooring solutions that meet the specific demands of industrial food production. One of the most popular options for food production facilities is Methyl Methacrylate resin. Methyl Methacrylate resin offers...

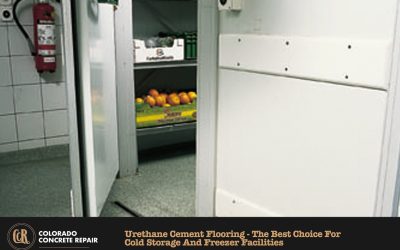

Urethane Cement Flooring: The Best Choice for Cold Storage and Freezer Facilities

At Colorado Concrete Repair, we understand the critical role that flooring plays in cold storage and freezer facilities. These environments require specialized flooring solutions that can withstand extreme temperatures and harsh conditions while ensuring safety and...

In the Commercial Concrete World, Are There Alternatives to New Concrete?

Commercial flooring is a significant expense. We offer some of the best prices in all of the Denver area, but we also recognize that even at our low prices, concrete can be expensive, especially if you need to redo the entirety of your flooring. It’s natural to want...

Aesthetic Versatility of Polished Concrete

Colorado Concrete Repair provides commercial flooring, specifically related to concrete and epoxy. Often, when our clients call us about epoxy, we find that what they really want and need is polished concrete. Epoxy remains an incredible option, but many find that...

Commercial Flooring Choices for High Traffic Properties

Colorado Concrete Repair Provides Commercial Concrete and Epoxy Services for High Traffic AreasWe sometimes forget how much abuse the floor beneath our feat takes. Every step we take puts some degree of pressure on our flooring, aging it slightly. Even the most high...