Be In The Know.

Blog

How to Maintain Concrete Floors at Commercial Properties

Concrete floors have a reputation for being one of the most low maintenance flooring solutions for commercial properties on the market. They need very little routine maintenance and are resistant to damage that could require extra work, saving you both time and money....

Understanding Load Bearing Capacities for Commercial Concrete Flooring

Concrete flooring is a good choice for commercial and industrial properties because of its durability and resilience. With natural strength, even a standard concrete with minimal thickness has impressive load bearing capabilities. 3000 psi is the standard of...

How Epoxy Flooring Can Increase Customer Satisfaction at Your Gym

A significant number of people in Denver are regular gym goers, and the area has a significant number of gyms to meet their needs. Staying competitive as a gym in Denver therefore requires not only the right equipment and fitness types to meet your customers’ needs,...

How to Clean an Auto Shop Epoxy Floor

Epoxy flooring is a leading solution for auto shops and garages. The epoxy is extremely durable and can stand up to cars, carts, toolboxes, and other heavy equipment that you regularly roll over the surface. It also will remain undamaged by the majority of chemicals...

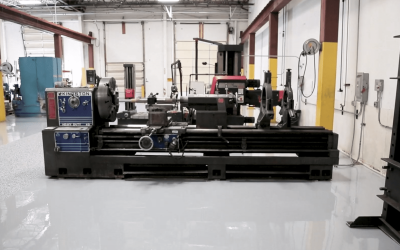

How to Tell If Your Warehouse or Industrial Facility Needs Concrete Leveling

Wherever a concrete floor is present, it is important that it is flat and perfectly level. In a manufacturing plant or a warehouse, the quality of your floor will directly impact safety and productivity. It is also important for maintaining the value and durability of...

Preparation Methods for an Epoxy Coating

Epoxy flooring can be an attractive and long lasting flooring option in an industrial or commercial property. But in order to achieve optimal flooring, epoxy prep is key. The epoxy flooring will only look as good and be as stable as its concrete base. Epoxy will not...

How Epoxy Floors in Your Colorado Warehouse Can Save You Money

Epoxy warehouse flooring in commercial properties is a great option for so many reasons. It is one of the more affordable options to install upfront, often only costing a few dollars per square foot, depending on your customization options, which is ideal when you...

Types of Epoxy Flooring and Choosing the Right One for Your Facility

Epoxy coating is a commercial flooring option that uses the foundation of a concrete floor with a layer of durable and resistant epoxy. It is one of several resinous floor types, in addition to urethane flooring, but epoxy itself also has a variety of options. The...

Calculating Long Term Commercial Floor Cost to Choose the Right Flooring Type for Your Commercial Property

Appearance and functionality are important when choosing the features for your commercial facility. But cost is almost always the deciding factor when choosing flooring. This includes more than just the cost of the initial installation and materials. A commercial...

Choosing the Best Flooring Option for Your Cannabis Facility in Denver

For marijuana growing operations, Denver and the surrounding area remain one of the top locations in the country for cannabis and marijuana production. But whether you are one of the original operations in Colorado or are opening a new production plant, you need a...